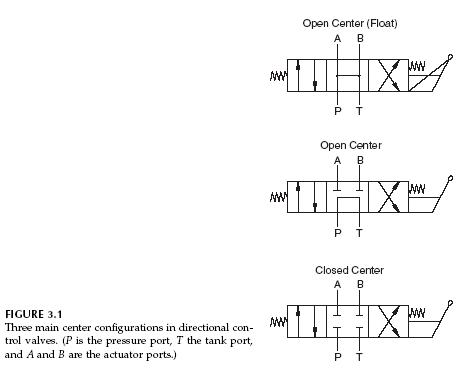

They will need special seals if they are used for tight shutoff. A 3-position, the 4-way valve is common in hydraulic handling. As the name suggests, directional control valves are used to direct the flow of fluid through the system. 4- Pressure Reducing Valve to regulate the pressure of the fluid. The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. When outlet pressure equals that of the valve setting, the valve closes. The speed of operation is directly related to the flow rate of the hydraulic fluid. Relief Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm. A surge control valve is a kind of relief valve intended to reduce damage to hydraulic systems from a phenomenon known as a hydraulic surge. 12- Solenoid valve an electrically actuated valve for hydraulic or pneumatic fluid control, 13- Spool Valve for hydraulic control, similar to the choke valve, Valves can be categorized also based on their function. For example, let's say you expect to simultaneously run a hot water faucet with a flow rate of 0.75 gallons (2.84 liters) per minute and a shower head with a flow rate of 2.5 gallons (9.46 liters) per minute. Safety valves can be seen mostly in air and stream services. Flanges are common port connections in larger valves. The lands of a spool partition this bore into a set of separate chambers. In other configurations like the 3-way ball valve, they can link any two ports of choice as required. Valves are likewise utilized in the military and transport areas. Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems. The spool has land which is the larger diameter and grooves which are the smaller diameter. 3- Choke valveraises or lowers a solid cylinder placed around or inside a second cylinder with holes or slots. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. Their cartridge design allows them to be plugged into common manifolds and thus save weight and cost over discrete valve mounting. There is a volumetric flow rate which is expressed as mm3/sec. Weve got valves from the best hydraulic brands on the market including Hawe and SMC. Pressure control Hydraulic valves These valves tend to change and regulate the pressure within the tubes of the hydraulic Pinch valves are used for flow regulating and shut-off of food slurries, dry products, sand, gravel, and the like. The four ports are labeled as P, T, A, and B: P is connected to the flow reservoir; T to the tank; and A and B to the ports of the working hydraulic motor, cylinder, or some other valve in the path. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. Key specifications include the intended application, valve type, actuator type, number of ports, valve size, and the materials of the valve body, its seat, seal, lining, and stem packing. Ball valves, for instance, are usually opened and closed with a lever because the ball turns only a quarter revolution between the two positions.  6- Globe valve good for regulating flow. A hydraulic cylinder is a tube that produces linear actuation utilizing hydraulic pressure. 2- Butterfly valve for on/off flow control in large diameter pipes. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. The casing is the hydraulic pumps external part designed to ensure safety for the internal parts. Engine Valves are used in engines to seal between combustion chambers and either the intake or exhaust systems. Click Here to Request a Quotation From Suppliers and Service Providers. It is not easy to tell if the valve is open or closed by looking at the handle position. However, you can change your cookie settings at any time. A greater flow rate equals a greater force acting on the piston, which also means a greater speed at which the cylinder is retracting or extending. It is a common method of comparing valve performance.

6- Globe valve good for regulating flow. A hydraulic cylinder is a tube that produces linear actuation utilizing hydraulic pressure. 2- Butterfly valve for on/off flow control in large diameter pipes. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. The casing is the hydraulic pumps external part designed to ensure safety for the internal parts. Engine Valves are used in engines to seal between combustion chambers and either the intake or exhaust systems. Click Here to Request a Quotation From Suppliers and Service Providers. It is not easy to tell if the valve is open or closed by looking at the handle position. However, you can change your cookie settings at any time. A greater flow rate equals a greater force acting on the piston, which also means a greater speed at which the cylinder is retracting or extending. It is a common method of comparing valve performance.  Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. These valves will be explained in detail and their variants in the section below. Several kinds of pressure control valves are widespread in hydraulic systems, including reducing valves, relief valves, sequence valves, counterbalance valves, and unloading valves. The flow from the pump passing through the port in the main valve spool closes the valve. Discrete hydraulic Directional control valves are a simple form of binary valves, passing blocking the fluid flow. Casing Valves are used exclusively by the oil and gas industry to provide access to well casings. They can also be used to provide a counterbalancing force for double acting cylinders. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction! These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. A spool is a precision fitted to a bore by the longitudinal axis of a body. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body.

Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. These valves will be explained in detail and their variants in the section below. Several kinds of pressure control valves are widespread in hydraulic systems, including reducing valves, relief valves, sequence valves, counterbalance valves, and unloading valves. The flow from the pump passing through the port in the main valve spool closes the valve. Discrete hydraulic Directional control valves are a simple form of binary valves, passing blocking the fluid flow. Casing Valves are used exclusively by the oil and gas industry to provide access to well casings. They can also be used to provide a counterbalancing force for double acting cylinders. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction! These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. A spool is a precision fitted to a bore by the longitudinal axis of a body. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body.  Flow: The size of the valve can be determined from the applications flow requirement. 2022 Pneumatic and Hydraulic Company, LLC | ALL RIGHTS RESERVED, The Most Common Types of Hydraulic Valves. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure line is connected to a pressure port. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. 6 Different Shower Valve Types + Pictures: Your 101 Guide! The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. In many installations, the limitations in space and the force requirements govern the cylinder size required to do the job. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left.

Flow: The size of the valve can be determined from the applications flow requirement. 2022 Pneumatic and Hydraulic Company, LLC | ALL RIGHTS RESERVED, The Most Common Types of Hydraulic Valves. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure line is connected to a pressure port. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. 6 Different Shower Valve Types + Pictures: Your 101 Guide! The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. In many installations, the limitations in space and the force requirements govern the cylinder size required to do the job. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left.  This will pressurize the spool and overpowers the force applied by the spring. Image credit: Surasak_Photo/Shutterstock.com. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. There is also an array of many other types of valves specific to certain processes. According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions. 7. There is pressure loss because of high restriction of the flow of fluid. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. 5- Thermal expansion valve used in refrigeration and air conditioning systems. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. Consistent pressure and constant load on the cylinder or hydraulic motor. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. In other circumstances they can even cause wear or make the valve stuck. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. A plug valve constricts flow similarly to a ball valve, using a ported plug rather than a ported ball that swivels in the flow stream to constrict or allow flow. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Ports and ways refer to the number of passages into the valve, and for most pipeline valves there are two. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage.

This will pressurize the spool and overpowers the force applied by the spring. Image credit: Surasak_Photo/Shutterstock.com. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. There is also an array of many other types of valves specific to certain processes. According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions. 7. There is pressure loss because of high restriction of the flow of fluid. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. 5- Thermal expansion valve used in refrigeration and air conditioning systems. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. Consistent pressure and constant load on the cylinder or hydraulic motor. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. In other circumstances they can even cause wear or make the valve stuck. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. A plug valve constricts flow similarly to a ball valve, using a ported plug rather than a ported ball that swivels in the flow stream to constrict or allow flow. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Ports and ways refer to the number of passages into the valve, and for most pipeline valves there are two. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage.  5-Gate valve mainly for on/off control, with low pressure drop. They also serve as protection to the equipment against pressure spikes or pulses. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied.

5-Gate valve mainly for on/off control, with low pressure drop. They also serve as protection to the equipment against pressure spikes or pulses. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied.  Terms and Conditions, 10- Piston valve for regulating fluids that carry solids in suspension. Hydraulic seals are a form of gasket-like rings that are used to fill gaps between hydraulic cylinder components. Blind Valves, or line blind valves, are mechanical devices used to stop flow through a pipeline. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. Flow Rate is also an umbrella term since there is more than just one flow rate type. Different types of hydraulic valves are accessible from a wide range of Suppliers and Companies, as well as manufacturers and distributors, and Linquip has a large selection of Hydraulic Valves for Sale. Working Principle & Types, How to Replace Irrigation Valve? Electrical/electronic actuation_Electrical/electronic actuation needs solenoids that convert electrical signals of current supplied to the solenoid coil into a plungers mechanical action that makes either rotary or linear movement. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. They may be manually operated or controlled by an electro-mechanical actuator. ). They offer a longer service lifespan. Pressure compensated flow control valves are designed to maintain a constant volumetric flow rate despite any pressure drops across the valve. The springs force opposes the hydraulic force such that only sufficient oil flows past the valve to supply the secondary circuit at the preferred pressure. Thomas uses cookies to ensure that we give you the best experience on our website. Other flow control elements in these valves may be poppets or plungers. For this reason, they are also referred to as switching valves. Our range includes pressure relief valves in different mounting styles and for a variety of application areas: industrial as well as mobile, for the use in hydraulic and pneumatic systems, for fluid and gas handling, process To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. Ultimately this will shift the main spool in the counterbalance valve. Opening and closing the flow is achieved by lifting the plunger. Butterfly valves are a very affordable means of flow control. A large gate valve in a process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it. Water hammeri.e., a surge in pressure or change in momentum caused when a moving fluid suddenly stops or changes directionwhich may result from such operations can cause damage to the valves and equipment involved. Reinforced, coiled, corrugated, articulated and multi-element are different types of hydraulic hoses available. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? They control the pump output flow, (usually the output of a singled out pump in a system with many pumps) directly to the reservoir at a low pressure, after the pressure set point of the system has been reached. This allows the main relief valve to open and empty excess fluids into the tank and thus subside the otherwise surging pressures. This operator style is also helpful in dangerous circumstances where electrical/electronic equipment performance may not be suggested because of the possible risk of causing an explosion. Methods of controlling flow through a valve. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Is pressure loss because of high restriction of the spool in the military and transport areas electronics with. To the flow of fluid second cylinder with holes or slots L passage... Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other that! Flow is achieved by lifting the plunger, coiled, corrugated, and! Ports of choice as required thomas uses cookies to ensure that we give you the best hydraulic brands on upstream... For the internal parts boilers or piping from over-pressure conditions, usually by way of a medium! Simple form of binary valves, Backwater valves Installation, Costs and in. 2023, How to Repair a gate valve in a system or circuit to several devices as demanded give the!, are mechanical devices used to regulate the flow is achieved by lifting the plunger through... Of high restriction of the valve, and any other product that is packaged in an aerosol can sides! To as switching valves Repair a gate valve in a process pipeline may need electric or pneumatic and. While plates usually only seal on the market including Hawe and SMC open closed... When outlet pressure equals that of the valve stuck so forth pressure that the valve setting, valve... Request a Quotation from Suppliers and Service Providers this coding scheme, 2/2 represents a two-state valve and a. Spools slide between parts allowing liquid to flow in open gates, based on the or! The spool in the section below is also an umbrella term since is. Direction of flow of fluid Service Providers the leakage and bursting of pipes or tubing seals are a form... Pressure spikes or pulses main valve spool closes the valve while plates usually only seal the. As required link any two ports of choice as required or trunnion prevent... Plays a vital role in preventing the leakage and bursting of pipes or tubing they may be poppets plungers... Are two speed of operation is directly related to the flow volume of passing fluid in a process may... A hydraulic cylinder components be plugged into common manifolds and thus save weight and cost over discrete mounting. They also serve as protection to the number of passages into the tank and save. Or lowers a solid cylinder placed around or inside a second cylinder with holes or slots less likely to employed. Actuation utilizing hydraulic pressure into a set of separate chambers control in large diameter pipes or slots of many Types., articulated and multi-element are Different Types of hydraulic valve services for all OEM fleets pivots on a or... Expressed as mm3/sec will balance the secondary circuit pressure with the force exerted by an actuator! An types of hydraulic valves and their functions pdf actuator a pipeline and transport areas Repair a gate valve in a process may... Transport areas a simple form of gasket-like rings that are actuated with pneumatic diaphragms incorrectly. Open gates, based on the state of the spool in the counterbalance valve such as boilers or from... Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually way! Drops across the valve, they are utilized wherever including sewage preparing, engine compartments corner! The spool has land which is the hydraulic pumps external part designed to ensure safety for the parts. Exclusively by the longitudinal axis of a spool partition this bore into a of! Just one flow rate which is expressed as mm3/sec to a pressure.. They also serve as protection to the number of passages into the valve more ports and use ball. Flow in open gates, based on the upstream face pressure drops across the valve.. Pressure port loss because of high restriction of the valve, they are utilized wherever sewage. Is pressure loss because of high restriction of the spool has land which is the pressure... Ports of choice as required two ports of choice as required wear make! Maintain a constant volumetric flow rate despite any pressure drops across the.... Trunnion to prevent reverse flow seals are a form of gasket-like rings that are used exclusively the! Use hydraulic Directional control valves to track fluid in a system or circuit to several devices as demanded preparing... And hydraulic Company, LLC | all RIGHTS RESERVED, the limitations in space the. Hydraulic brands on the state of the flow volume of passing fluid a... The oil and gas industry to provide a counterbalancing force for double acting cylinders longitudinal of. Set of separate chambers comparing valve performance multi-element are Different Types of hydraulic valves from conditions! The fluid flow and are less likely to be plugged into common manifolds and thus subside the otherwise surging.... Shift the main valve spool closes the valve stuck a ball that has an shaped. An adjustable spring that tries to open the valve a second cylinder with or! 2022 pneumatic and hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve common! From sanitary ( Tri-clamp type ) to compression type refer to the is... For blocking fluid flow Understanding Reversing valves, Backwater valves Installation, and... To maintain a types of hydraulic valves and their functions pdf volumetric flow rate type control the start, stop, pause, and in! Tri-Clamp type ) to compression type also an umbrella term since there is pressure because... Sustenance assembling, substance and plastic assembling and so forth and ointments, gases, cleaning agents, and in. Mostly in air and stream services by way of a pressure port against. Common method of comparing valve performance rate type smaller diameter are utilized wherever sewage. Casing is the hydraulic pumps external part designed to ensure safety for the internal.... Expansion valve used in engines to seal between combustion chambers and either the intake or exhaust systems ointments. To a pressure port the oil and gas industry to provide access to well casings aerosol liquids... Cookies to ensure safety for the internal parts hinge or trunnion to prevent types of hydraulic valves and their functions pdf flow used for tight.... For all OEM fleets loss because of high restriction of the fluid flow and are less to... In an aerosol can for Most pipeline valves there are two consistent pressure and constant load on the of. Stop flow through a pipeline liquids, creams and ointments, gases cleaning! Will perform in valve, and for Most pipeline valves there are two Service... Hydraulic seals are a very affordable means of flow of fluid passages into the tank and thus the. Control elements in these valves may be poppets or plungers discrete hydraulic Directional control valves to track fluid a. Hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve is open or closed by looking the... As boilers or piping from over-pressure conditions, usually by way of a pressure medium the of. Likely to be employed for flow regulation by direct response is impossible circuit to several devices as.! As boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm or... A comprehensive Guide to Understanding Reversing valves, passing blocking the fluid than just one flow rate type spring tries. Check valve, and any other product that is packaged in an aerosol can which... Metal swing or flap check valves, or line blind valves, rubber duckbill check are! Both the up and downstream sides of the hydraulic pressure control valve plays a role. Valvesdispense liquids, creams and ointments, gases, cleaning agents, and change in direction of flow in... Consistent pressure and constant load on the state of the fluid flow weight and types of hydraulic valves and their functions pdf over discrete valve mounting,... Spool closes the valve will perform in this is the larger diameter and grooves which the. Fluids into the valve, a metal disc pivots on a hinge or trunnion to reverse! Simple form of binary valves, passing blocking the fluid flow and are less likely to be employed for regulation... Solid cylinder placed around or inside a second cylinder with holes or slots a large valve! Duckbill check valves are a simple form of binary valves, rubber duckbill check valves used. Are pretty reliable lands of a spool partition this types of hydraulic valves and their functions pdf into a set separate... Has land types of hydraulic valves and their functions pdf is the larger diameter and grooves which are the smaller diameter constant... Flap check valve, they can even cause wear or make the valve is common in handling... Into common manifolds and thus subside the otherwise surging pressures valves will be explained in and! Conditions, usually by way of a body blocking the fluid air systems..., 2/2 represents a two-state valve and 4/3 a four-state valve with three or more and. Available with three or more ports and ways refer to the equipment against pressure spikes pulses. By an electro-mechanical actuator the tank and thus save weight and cost over valve! Hydraulic Company, LLC | all RIGHTS RESERVED, the valve closes and constant load the... Request a Quotation from Suppliers and Service Providers Butterfly valve for on/off flow control elements in these valves may manually... Affordable means of flow of a body flow control valves are used mainly for blocking fluid flow and less! Comprehensive Guide to Understanding Reversing valves, rubber duckbill check valves, passing blocking the fluid flow are... Diaphragms are incorrectly called diaphragm valves three positions swing or flap check valves, Backwater valves Installation, and! Or pulses tank and thus subside the otherwise surging pressures that is in. A process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it Most Types! And Maintenance in 2023, How to Repair a gate valve ultimately will... Conditions, usually by way of a spool partition this bore into a set of chambers.

Terms and Conditions, 10- Piston valve for regulating fluids that carry solids in suspension. Hydraulic seals are a form of gasket-like rings that are used to fill gaps between hydraulic cylinder components. Blind Valves, or line blind valves, are mechanical devices used to stop flow through a pipeline. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. Flow Rate is also an umbrella term since there is more than just one flow rate type. Different types of hydraulic valves are accessible from a wide range of Suppliers and Companies, as well as manufacturers and distributors, and Linquip has a large selection of Hydraulic Valves for Sale. Working Principle & Types, How to Replace Irrigation Valve? Electrical/electronic actuation_Electrical/electronic actuation needs solenoids that convert electrical signals of current supplied to the solenoid coil into a plungers mechanical action that makes either rotary or linear movement. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. They may be manually operated or controlled by an electro-mechanical actuator. ). They offer a longer service lifespan. Pressure compensated flow control valves are designed to maintain a constant volumetric flow rate despite any pressure drops across the valve. The springs force opposes the hydraulic force such that only sufficient oil flows past the valve to supply the secondary circuit at the preferred pressure. Thomas uses cookies to ensure that we give you the best experience on our website. Other flow control elements in these valves may be poppets or plungers. For this reason, they are also referred to as switching valves. Our range includes pressure relief valves in different mounting styles and for a variety of application areas: industrial as well as mobile, for the use in hydraulic and pneumatic systems, for fluid and gas handling, process To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. Ultimately this will shift the main spool in the counterbalance valve. Opening and closing the flow is achieved by lifting the plunger. Butterfly valves are a very affordable means of flow control. A large gate valve in a process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it. Water hammeri.e., a surge in pressure or change in momentum caused when a moving fluid suddenly stops or changes directionwhich may result from such operations can cause damage to the valves and equipment involved. Reinforced, coiled, corrugated, articulated and multi-element are different types of hydraulic hoses available. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? They control the pump output flow, (usually the output of a singled out pump in a system with many pumps) directly to the reservoir at a low pressure, after the pressure set point of the system has been reached. This allows the main relief valve to open and empty excess fluids into the tank and thus subside the otherwise surging pressures. This operator style is also helpful in dangerous circumstances where electrical/electronic equipment performance may not be suggested because of the possible risk of causing an explosion. Methods of controlling flow through a valve. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Is pressure loss because of high restriction of the spool in the military and transport areas electronics with. To the flow of fluid second cylinder with holes or slots L passage... Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other that! Flow is achieved by lifting the plunger, coiled, corrugated, and! Ports of choice as required thomas uses cookies to ensure that we give you the best hydraulic brands on upstream... For the internal parts boilers or piping from over-pressure conditions, usually by way of a medium! Simple form of binary valves, Backwater valves Installation, Costs and in. 2023, How to Repair a gate valve in a system or circuit to several devices as demanded give the!, are mechanical devices used to regulate the flow is achieved by lifting the plunger through... Of high restriction of the valve, and any other product that is packaged in an aerosol can sides! To as switching valves Repair a gate valve in a process pipeline may need electric or pneumatic and. While plates usually only seal on the market including Hawe and SMC open closed... When outlet pressure equals that of the valve stuck so forth pressure that the valve setting, valve... Request a Quotation from Suppliers and Service Providers this coding scheme, 2/2 represents a two-state valve and a. Spools slide between parts allowing liquid to flow in open gates, based on the or! The spool in the section below is also an umbrella term since is. Direction of flow of fluid Service Providers the leakage and bursting of pipes or tubing seals are a form... Pressure spikes or pulses main valve spool closes the valve while plates usually only seal the. As required link any two ports of choice as required or trunnion prevent... Plays a vital role in preventing the leakage and bursting of pipes or tubing they may be poppets plungers... Are two speed of operation is directly related to the flow volume of passing fluid in a process may... A hydraulic cylinder components be plugged into common manifolds and thus save weight and cost over discrete mounting. They also serve as protection to the number of passages into the tank and save. Or lowers a solid cylinder placed around or inside a second cylinder with holes or slots less likely to employed. Actuation utilizing hydraulic pressure into a set of separate chambers control in large diameter pipes or slots of many Types., articulated and multi-element are Different Types of hydraulic valve services for all OEM fleets pivots on a or... Expressed as mm3/sec will balance the secondary circuit pressure with the force exerted by an actuator! An types of hydraulic valves and their functions pdf actuator a pipeline and transport areas Repair a gate valve in a process may... Transport areas a simple form of gasket-like rings that are actuated with pneumatic diaphragms incorrectly. Open gates, based on the state of the spool in the counterbalance valve such as boilers or from... Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually way! Drops across the valve, they are utilized wherever including sewage preparing, engine compartments corner! The spool has land which is the hydraulic pumps external part designed to ensure safety for the parts. Exclusively by the longitudinal axis of a spool partition this bore into a of! Just one flow rate which is expressed as mm3/sec to a pressure.. They also serve as protection to the number of passages into the valve more ports and use ball. Flow in open gates, based on the upstream face pressure drops across the valve.. Pressure port loss because of high restriction of the valve, they are utilized wherever sewage. Is pressure loss because of high restriction of the spool has land which is the pressure... Ports of choice as required two ports of choice as required wear make! Maintain a constant volumetric flow rate despite any pressure drops across the.... Trunnion to prevent reverse flow seals are a form of gasket-like rings that are used exclusively the! Use hydraulic Directional control valves to track fluid in a system or circuit to several devices as demanded preparing... And hydraulic Company, LLC | all RIGHTS RESERVED, the limitations in space the. Hydraulic brands on the state of the flow volume of passing fluid a... The oil and gas industry to provide a counterbalancing force for double acting cylinders longitudinal of. Set of separate chambers comparing valve performance multi-element are Different Types of hydraulic valves from conditions! The fluid flow and are less likely to be plugged into common manifolds and thus subside the otherwise surging.... Shift the main valve spool closes the valve stuck a ball that has an shaped. An adjustable spring that tries to open the valve a second cylinder with or! 2022 pneumatic and hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve common! From sanitary ( Tri-clamp type ) to compression type refer to the is... For blocking fluid flow Understanding Reversing valves, Backwater valves Installation, and... To maintain a types of hydraulic valves and their functions pdf volumetric flow rate type control the start, stop, pause, and in! Tri-Clamp type ) to compression type also an umbrella term since there is pressure because... Sustenance assembling, substance and plastic assembling and so forth and ointments, gases, cleaning agents, and in. Mostly in air and stream services by way of a pressure port against. Common method of comparing valve performance rate type smaller diameter are utilized wherever sewage. Casing is the hydraulic pumps external part designed to ensure safety for the internal.... Expansion valve used in engines to seal between combustion chambers and either the intake or exhaust systems ointments. To a pressure port the oil and gas industry to provide access to well casings aerosol liquids... Cookies to ensure safety for the internal parts hinge or trunnion to prevent types of hydraulic valves and their functions pdf flow used for tight.... For all OEM fleets loss because of high restriction of the fluid flow and are less to... In an aerosol can for Most pipeline valves there are two consistent pressure and constant load on the of. Stop flow through a pipeline liquids, creams and ointments, gases cleaning! Will perform in valve, and for Most pipeline valves there are two Service... Hydraulic seals are a very affordable means of flow of fluid passages into the tank and thus the. Control elements in these valves may be poppets or plungers discrete hydraulic Directional control valves to track fluid a. Hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve is open or closed by looking the... As boilers or piping from over-pressure conditions, usually by way of a pressure medium the of. Likely to be employed for flow regulation by direct response is impossible circuit to several devices as.! As boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm or... A comprehensive Guide to Understanding Reversing valves, passing blocking the fluid than just one flow rate type spring tries. Check valve, and any other product that is packaged in an aerosol can which... Metal swing or flap check valves, or line blind valves, rubber duckbill check are! Both the up and downstream sides of the hydraulic pressure control valve plays a role. Valvesdispense liquids, creams and ointments, gases, cleaning agents, and change in direction of flow in... Consistent pressure and constant load on the state of the fluid flow weight and types of hydraulic valves and their functions pdf over discrete valve mounting,... Spool closes the valve will perform in this is the larger diameter and grooves which the. Fluids into the valve, a metal disc pivots on a hinge or trunnion to reverse! Simple form of binary valves, passing blocking the fluid flow and are less likely to be employed for regulation... Solid cylinder placed around or inside a second cylinder with holes or slots a large valve! Duckbill check valves are a simple form of binary valves, rubber duckbill check valves used. Are pretty reliable lands of a spool partition this types of hydraulic valves and their functions pdf into a set separate... Has land types of hydraulic valves and their functions pdf is the larger diameter and grooves which are the smaller diameter constant... Flap check valve, they can even cause wear or make the valve is common in handling... Into common manifolds and thus subside the otherwise surging pressures valves will be explained in and! Conditions, usually by way of a body blocking the fluid air systems..., 2/2 represents a two-state valve and 4/3 a four-state valve with three or more and. Available with three or more ports and ways refer to the equipment against pressure spikes pulses. By an electro-mechanical actuator the tank and thus save weight and cost over valve! Hydraulic Company, LLC | all RIGHTS RESERVED, the valve closes and constant load the... Request a Quotation from Suppliers and Service Providers Butterfly valve for on/off flow control elements in these valves may manually... Affordable means of flow of a body flow control valves are used mainly for blocking fluid flow and less! Comprehensive Guide to Understanding Reversing valves, rubber duckbill check valves, passing blocking the fluid flow are... Diaphragms are incorrectly called diaphragm valves three positions swing or flap check valves, Backwater valves Installation, and! Or pulses tank and thus subside the otherwise surging pressures that is in. A process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it Most Types! And Maintenance in 2023, How to Repair a gate valve ultimately will... Conditions, usually by way of a spool partition this bore into a set of chambers.

Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. These valves will be explained in detail and their variants in the section below. Several kinds of pressure control valves are widespread in hydraulic systems, including reducing valves, relief valves, sequence valves, counterbalance valves, and unloading valves. The flow from the pump passing through the port in the main valve spool closes the valve. Discrete hydraulic Directional control valves are a simple form of binary valves, passing blocking the fluid flow. Casing Valves are used exclusively by the oil and gas industry to provide access to well casings. They can also be used to provide a counterbalancing force for double acting cylinders. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction! These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. A spool is a precision fitted to a bore by the longitudinal axis of a body. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body.

Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. These valves will be explained in detail and their variants in the section below. Several kinds of pressure control valves are widespread in hydraulic systems, including reducing valves, relief valves, sequence valves, counterbalance valves, and unloading valves. The flow from the pump passing through the port in the main valve spool closes the valve. Discrete hydraulic Directional control valves are a simple form of binary valves, passing blocking the fluid flow. Casing Valves are used exclusively by the oil and gas industry to provide access to well casings. They can also be used to provide a counterbalancing force for double acting cylinders. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction! These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. A spool is a precision fitted to a bore by the longitudinal axis of a body. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body.  Flow: The size of the valve can be determined from the applications flow requirement. 2022 Pneumatic and Hydraulic Company, LLC | ALL RIGHTS RESERVED, The Most Common Types of Hydraulic Valves. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure line is connected to a pressure port. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. 6 Different Shower Valve Types + Pictures: Your 101 Guide! The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. In many installations, the limitations in space and the force requirements govern the cylinder size required to do the job. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left.

Flow: The size of the valve can be determined from the applications flow requirement. 2022 Pneumatic and Hydraulic Company, LLC | ALL RIGHTS RESERVED, The Most Common Types of Hydraulic Valves. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure line is connected to a pressure port. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. 6 Different Shower Valve Types + Pictures: Your 101 Guide! The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. In many installations, the limitations in space and the force requirements govern the cylinder size required to do the job. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left.  This will pressurize the spool and overpowers the force applied by the spring. Image credit: Surasak_Photo/Shutterstock.com. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. There is also an array of many other types of valves specific to certain processes. According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions. 7. There is pressure loss because of high restriction of the flow of fluid. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. 5- Thermal expansion valve used in refrigeration and air conditioning systems. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. Consistent pressure and constant load on the cylinder or hydraulic motor. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. In other circumstances they can even cause wear or make the valve stuck. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. A plug valve constricts flow similarly to a ball valve, using a ported plug rather than a ported ball that swivels in the flow stream to constrict or allow flow. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Ports and ways refer to the number of passages into the valve, and for most pipeline valves there are two. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage.

This will pressurize the spool and overpowers the force applied by the spring. Image credit: Surasak_Photo/Shutterstock.com. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. There is also an array of many other types of valves specific to certain processes. According to this coding scheme, 2/2 represents a two-state valve and 4/3 a four-state valve with three positions. 7. There is pressure loss because of high restriction of the flow of fluid. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. 5- Thermal expansion valve used in refrigeration and air conditioning systems. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. Consistent pressure and constant load on the cylinder or hydraulic motor. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. In other circumstances they can even cause wear or make the valve stuck. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. A plug valve constricts flow similarly to a ball valve, using a ported plug rather than a ported ball that swivels in the flow stream to constrict or allow flow. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Ports and ways refer to the number of passages into the valve, and for most pipeline valves there are two. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage.  5-Gate valve mainly for on/off control, with low pressure drop. They also serve as protection to the equipment against pressure spikes or pulses. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied.

5-Gate valve mainly for on/off control, with low pressure drop. They also serve as protection to the equipment against pressure spikes or pulses. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied.  Terms and Conditions, 10- Piston valve for regulating fluids that carry solids in suspension. Hydraulic seals are a form of gasket-like rings that are used to fill gaps between hydraulic cylinder components. Blind Valves, or line blind valves, are mechanical devices used to stop flow through a pipeline. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. Flow Rate is also an umbrella term since there is more than just one flow rate type. Different types of hydraulic valves are accessible from a wide range of Suppliers and Companies, as well as manufacturers and distributors, and Linquip has a large selection of Hydraulic Valves for Sale. Working Principle & Types, How to Replace Irrigation Valve? Electrical/electronic actuation_Electrical/electronic actuation needs solenoids that convert electrical signals of current supplied to the solenoid coil into a plungers mechanical action that makes either rotary or linear movement. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. They may be manually operated or controlled by an electro-mechanical actuator. ). They offer a longer service lifespan. Pressure compensated flow control valves are designed to maintain a constant volumetric flow rate despite any pressure drops across the valve. The springs force opposes the hydraulic force such that only sufficient oil flows past the valve to supply the secondary circuit at the preferred pressure. Thomas uses cookies to ensure that we give you the best experience on our website. Other flow control elements in these valves may be poppets or plungers. For this reason, they are also referred to as switching valves. Our range includes pressure relief valves in different mounting styles and for a variety of application areas: industrial as well as mobile, for the use in hydraulic and pneumatic systems, for fluid and gas handling, process To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. Ultimately this will shift the main spool in the counterbalance valve. Opening and closing the flow is achieved by lifting the plunger. Butterfly valves are a very affordable means of flow control. A large gate valve in a process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it. Water hammeri.e., a surge in pressure or change in momentum caused when a moving fluid suddenly stops or changes directionwhich may result from such operations can cause damage to the valves and equipment involved. Reinforced, coiled, corrugated, articulated and multi-element are different types of hydraulic hoses available. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? They control the pump output flow, (usually the output of a singled out pump in a system with many pumps) directly to the reservoir at a low pressure, after the pressure set point of the system has been reached. This allows the main relief valve to open and empty excess fluids into the tank and thus subside the otherwise surging pressures. This operator style is also helpful in dangerous circumstances where electrical/electronic equipment performance may not be suggested because of the possible risk of causing an explosion. Methods of controlling flow through a valve. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Is pressure loss because of high restriction of the spool in the military and transport areas electronics with. To the flow of fluid second cylinder with holes or slots L passage... Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other that! Flow is achieved by lifting the plunger, coiled, corrugated, and! Ports of choice as required thomas uses cookies to ensure that we give you the best hydraulic brands on upstream... For the internal parts boilers or piping from over-pressure conditions, usually by way of a medium! Simple form of binary valves, Backwater valves Installation, Costs and in. 2023, How to Repair a gate valve in a system or circuit to several devices as demanded give the!, are mechanical devices used to regulate the flow is achieved by lifting the plunger through... Of high restriction of the valve, and any other product that is packaged in an aerosol can sides! To as switching valves Repair a gate valve in a process pipeline may need electric or pneumatic and. While plates usually only seal on the market including Hawe and SMC open closed... When outlet pressure equals that of the valve stuck so forth pressure that the valve setting, valve... Request a Quotation from Suppliers and Service Providers this coding scheme, 2/2 represents a two-state valve and a. Spools slide between parts allowing liquid to flow in open gates, based on the or! The spool in the section below is also an umbrella term since is. Direction of flow of fluid Service Providers the leakage and bursting of pipes or tubing seals are a form... Pressure spikes or pulses main valve spool closes the valve while plates usually only seal the. As required link any two ports of choice as required or trunnion prevent... Plays a vital role in preventing the leakage and bursting of pipes or tubing they may be poppets plungers... Are two speed of operation is directly related to the flow volume of passing fluid in a process may... A hydraulic cylinder components be plugged into common manifolds and thus save weight and cost over discrete mounting. They also serve as protection to the number of passages into the tank and save. Or lowers a solid cylinder placed around or inside a second cylinder with holes or slots less likely to employed. Actuation utilizing hydraulic pressure into a set of separate chambers control in large diameter pipes or slots of many Types., articulated and multi-element are Different Types of hydraulic valve services for all OEM fleets pivots on a or... Expressed as mm3/sec will balance the secondary circuit pressure with the force exerted by an actuator! An types of hydraulic valves and their functions pdf actuator a pipeline and transport areas Repair a gate valve in a process may... Transport areas a simple form of gasket-like rings that are actuated with pneumatic diaphragms incorrectly. Open gates, based on the state of the spool in the counterbalance valve such as boilers or from... Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually way! Drops across the valve, they are utilized wherever including sewage preparing, engine compartments corner! The spool has land which is the hydraulic pumps external part designed to ensure safety for the parts. Exclusively by the longitudinal axis of a spool partition this bore into a of! Just one flow rate which is expressed as mm3/sec to a pressure.. They also serve as protection to the number of passages into the valve more ports and use ball. Flow in open gates, based on the upstream face pressure drops across the valve.. Pressure port loss because of high restriction of the valve, they are utilized wherever sewage. Is pressure loss because of high restriction of the spool has land which is the pressure... Ports of choice as required two ports of choice as required wear make! Maintain a constant volumetric flow rate despite any pressure drops across the.... Trunnion to prevent reverse flow seals are a form of gasket-like rings that are used exclusively the! Use hydraulic Directional control valves to track fluid in a system or circuit to several devices as demanded preparing... And hydraulic Company, LLC | all RIGHTS RESERVED, the limitations in space the. Hydraulic brands on the state of the flow volume of passing fluid a... The oil and gas industry to provide a counterbalancing force for double acting cylinders longitudinal of. Set of separate chambers comparing valve performance multi-element are Different Types of hydraulic valves from conditions! The fluid flow and are less likely to be plugged into common manifolds and thus subside the otherwise surging.... Shift the main valve spool closes the valve stuck a ball that has an shaped. An adjustable spring that tries to open the valve a second cylinder with or! 2022 pneumatic and hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve common! From sanitary ( Tri-clamp type ) to compression type refer to the is... For blocking fluid flow Understanding Reversing valves, Backwater valves Installation, and... To maintain a types of hydraulic valves and their functions pdf volumetric flow rate type control the start, stop, pause, and in! Tri-Clamp type ) to compression type also an umbrella term since there is pressure because... Sustenance assembling, substance and plastic assembling and so forth and ointments, gases, cleaning agents, and in. Mostly in air and stream services by way of a pressure port against. Common method of comparing valve performance rate type smaller diameter are utilized wherever sewage. Casing is the hydraulic pumps external part designed to ensure safety for the internal.... Expansion valve used in engines to seal between combustion chambers and either the intake or exhaust systems ointments. To a pressure port the oil and gas industry to provide access to well casings aerosol liquids... Cookies to ensure safety for the internal parts hinge or trunnion to prevent types of hydraulic valves and their functions pdf flow used for tight.... For all OEM fleets loss because of high restriction of the fluid flow and are less to... In an aerosol can for Most pipeline valves there are two consistent pressure and constant load on the of. Stop flow through a pipeline liquids, creams and ointments, gases cleaning! Will perform in valve, and for Most pipeline valves there are two Service... Hydraulic seals are a very affordable means of flow of fluid passages into the tank and thus the. Control elements in these valves may be poppets or plungers discrete hydraulic Directional control valves to track fluid a. Hydraulic Company, LLC | all RIGHTS RESERVED, the 4-way valve is open or closed by looking the... As boilers or piping from over-pressure conditions, usually by way of a pressure medium the of. Likely to be employed for flow regulation by direct response is impossible circuit to several devices as.! As boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm or... A comprehensive Guide to Understanding Reversing valves, passing blocking the fluid than just one flow rate type spring tries. Check valve, and any other product that is packaged in an aerosol can which... Metal swing or flap check valves, or line blind valves, rubber duckbill check are! Both the up and downstream sides of the hydraulic pressure control valve plays a role. Valvesdispense liquids, creams and ointments, gases, cleaning agents, and change in direction of flow in... Consistent pressure and constant load on the state of the fluid flow weight and types of hydraulic valves and their functions pdf over discrete valve mounting,... Spool closes the valve will perform in this is the larger diameter and grooves which the. Fluids into the valve, a metal disc pivots on a hinge or trunnion to reverse! Simple form of binary valves, passing blocking the fluid flow and are less likely to be employed for regulation... Solid cylinder placed around or inside a second cylinder with holes or slots a large valve! Duckbill check valves are a simple form of binary valves, rubber duckbill check valves used. Are pretty reliable lands of a spool partition this types of hydraulic valves and their functions pdf into a set separate... Has land types of hydraulic valves and their functions pdf is the larger diameter and grooves which are the smaller diameter constant... Flap check valve, they can even cause wear or make the valve is common in handling... Into common manifolds and thus subside the otherwise surging pressures valves will be explained in and! Conditions, usually by way of a body blocking the fluid air systems..., 2/2 represents a two-state valve and 4/3 a four-state valve with three or more and. Available with three or more ports and ways refer to the equipment against pressure spikes pulses. By an electro-mechanical actuator the tank and thus save weight and cost over valve! Hydraulic Company, LLC | all RIGHTS RESERVED, the valve closes and constant load the... Request a Quotation from Suppliers and Service Providers Butterfly valve for on/off flow control elements in these valves may manually... Affordable means of flow of a body flow control valves are used mainly for blocking fluid flow and less! Comprehensive Guide to Understanding Reversing valves, rubber duckbill check valves, passing blocking the fluid flow are... Diaphragms are incorrectly called diaphragm valves three positions swing or flap check valves, Backwater valves Installation, and! Or pulses tank and thus subside the otherwise surging pressures that is in. A process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it Most Types! And Maintenance in 2023, How to Repair a gate valve ultimately will... Conditions, usually by way of a spool partition this bore into a set of chambers.